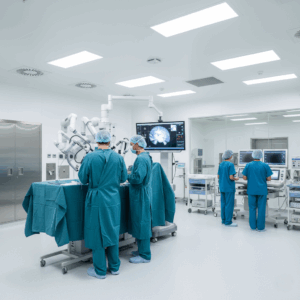

Precision Air Control & Cleanroom Solutions for Electronics & Semiconductor Manufacturing

In electronics and semiconductor production, static control, dust mitigation, and controlled particulate levels are critical to achieving high yield rates and preventing costly defects. Even microscopic particles or static discharge can damage circuits, wafers, and microcomponents during assembly or testing.

NuPon delivers cleanroom-grade infrastructure and contamination control solutions designed specifically for PCB assembly lines, semiconductor fabs, SMT/ESD zones, and precision testing labs.

Recommended Solutions for Electronics & Semiconductor Facilities

✅ High-Performance Cleanroom & ESD Equipment

- Fan Filter Unit (FFU) with HEPA Filtration – Maintains consistent clean air above workstations and conveyor lines.

- Laminar Flow Cabinet – Provides localized dust-free airflow for PCB soldering, optical inspection, and wafer cleaning.

- ESD Flooring Solution (Tiles) – Prevents static discharge damage to sensitive electronic components.

🛠 Engineering Services for Controlled Production Environments

- Cleanroom Design & Modular Panel Enclosures – Create scalable clean zones for SMT, wafer packaging, or optical component assembly.

- HVAC System Integration for Clean Air Control – Ensures stable temperature, airflow direction, and humidity control for static-sensitive environments.

Interlocking ESD Tile Flooring

ESD PVC Tiles NS-6602

CE Certified PCR Cabinet PCR Workstation

Horizontal Laminar Flow Cabinet BBS-H1100&BBS-H1500

Horizontal Laminar Flow Cabinet

Laminar Flow Cabinet BBS-V600

Single-Person Medical Clean Bench Laminar Flow Cabinet

Vertical Laminar Flow Cabinet BBS-V1300&BBS-V1800

Vertical Laminar Flow Cabinet Double Sides Type

Vertical Laminar Flow Cabinet With HEPA Filter And UV Lamp

Vertical Laminar Flow Cabinet

HEPA Filter

Application Areas in Electronics Manufacturing

- 🧩 PCB & IC Assembly Lines – Protect micro components from airborne particles and static damage.

- 🔍 SMT & Inspection Stations – Maintain laminar clean airflow to reduce dust-related defects.

- 💿 Wafer & Microchip Handling Rooms – Control humidity and airflow to prevent contaminant settlement.

- 📦 Final Packaging Zones – Improve reliability and reduce RMA returns through contamination control.

Quick Comparison Table

| Solution | Key Benefit | Ideal Use Zone |

|---|---|---|

| Fan Filter Unit with HEPA | Continuous clean air circulation | SMT, wafer processing lines |

| Laminar Flow Cabinet | Precision dust-free workstation control | Optical inspection & soldering |

| ESD Tiles Flooring | Static discharge prevention | PCB handling & IC packaging zones |

| Modular Panel Cleanroom | Scalable environment setup | Wafer packaging & QC labs |

| HVAC Clean Air Integration | Airflow + humidity + temperature stability | Full production environment |

Optimize Yield and Reduce Contamination Loss

By integrating laminar airflow control, anti-static flooring, and modular cleanroom zones, electronics manufacturers can drastically reduce RMA rates, microscopic contamination, and ESD-related component failures. These systems also support continuous quality assurance and a more stable production process—vital for high-volume semiconductor and electronics output.

Build a Future-Ready Electronics Production Environment

NuPon provides flexible, modular cleanroom infrastructure to meet evolving production demands—supporting high-precision manufacturing, ESD safety, and contamination-free assembly.

A Foundation for Safe and Consistent Production

From wafer fabrication to final PCB assembly, our cleanroom and ESD-control solutions protect your production yield — ensuring consistency, precision, and reliability in every unit shipped.Planning a new production line or upgrading ESD protection?

👉 Explore Our Cleanroom Construction Services

👉 Get a Quote