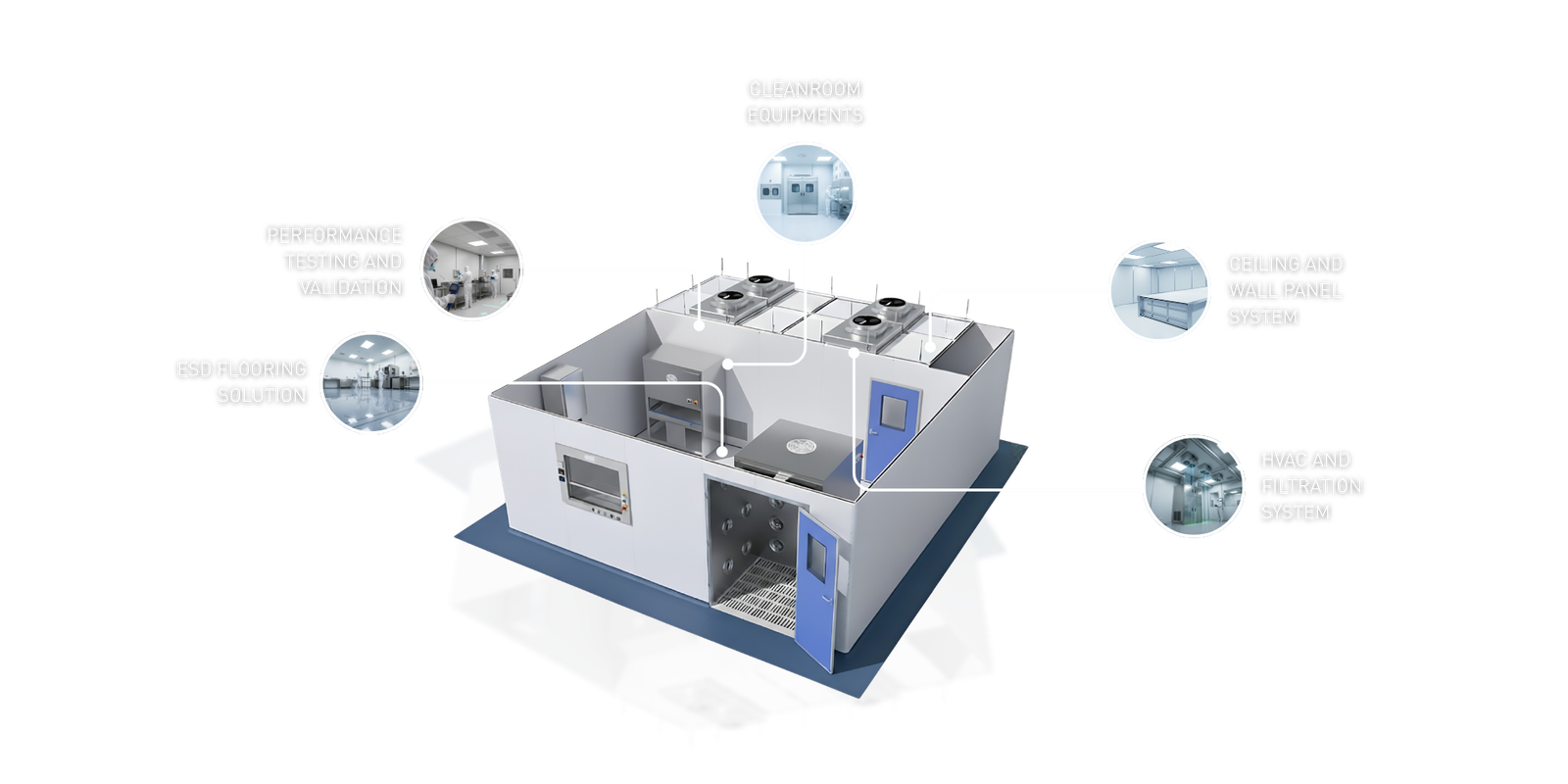

Cleanroom Construction Design & Build

Explore our specialized services designed to ensure efficiency, compliance, and reliability at every stage.

Precision. Performance. Compliance.

At NuPON Cleanroom Construction, we deliver turnkey cleanroom solutions engineered for performance and built for compliance. From design and installation to validation and certification, our services ensure your controlled environment meets the highest ISO and GMP standards.

Clean Room Design

Precision-Engineered Cleanrooms, Designed for Performance and Compliance

Our cleanroom design services blend engineering accuracy with regulatory expertise. From concept to completion, we create environments optimized for airflow, contamination control, and compliance — ensuring your facility operates flawlessly from day one.

Precision-Engineered Layouts

Optimized airflow and contamination control from concept to completion

Designed for Compliance

Meets ISO and GMP standards through validated engineering principles

Designed for Compliance

Meets ISO and GMP standards through validated engineering principles

Modular Clean Booth

Fast, Flexible, and Fully Compliant Modular Solutions

Achieve ISO-grade cleanliness without the complexity of full-scale construction. Our modular clean booths offer customizable layouts, quick installation, and total flexibility — ideal for expanding production or creating dedicated clean zones within existing spaces.

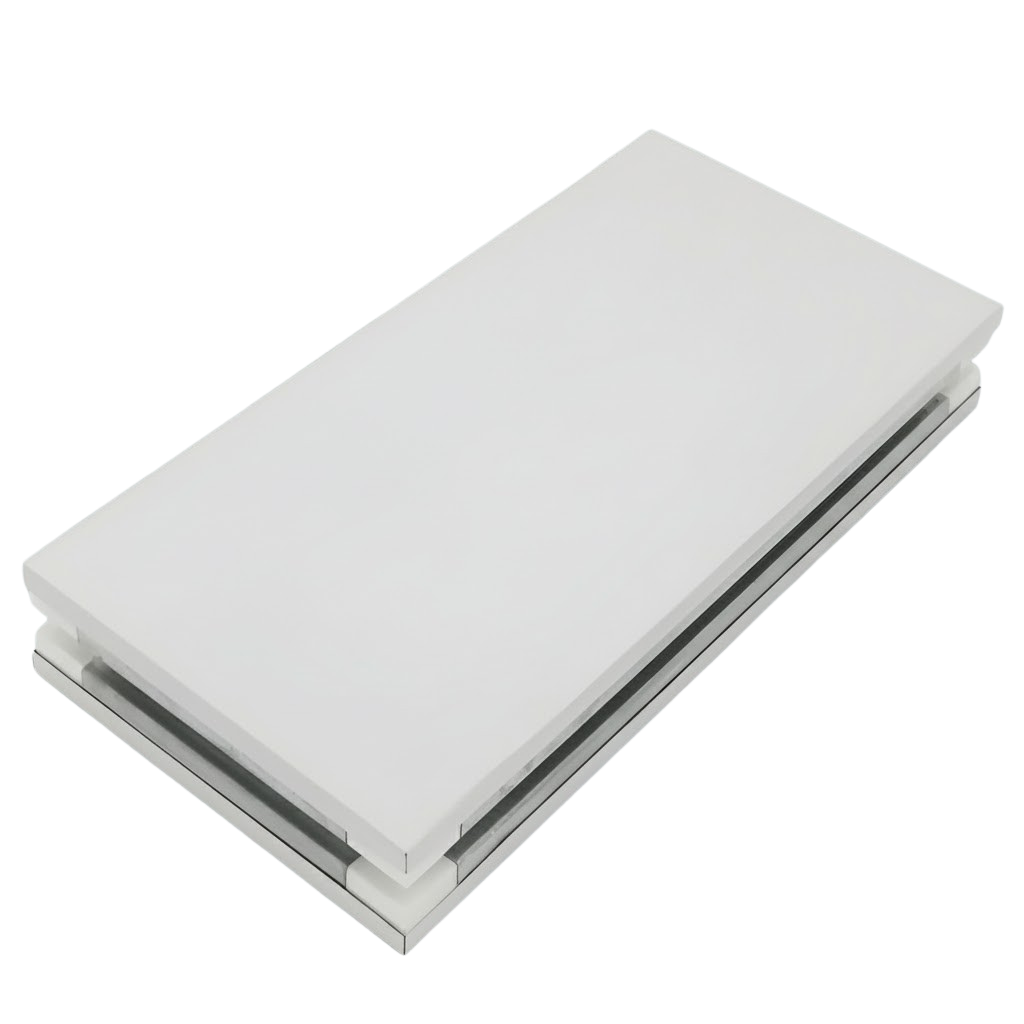

Wall and Ceiling Sandwich Panel Enclosure

High-Performance Enclosures That Define Cleanroom Integrity

Our wall and ceiling sandwich panels are designed for airtight integrity, superior insulation, and hygienic performance. Resistant to microbial growth and easy to maintain, they deliver a seamless, professional finish that supports long-term cleanroom compliance.

Engineered Layers of Excellence

Each panel is crafted for airtight performance, superior insulation, and lasting cleanroom integrity.

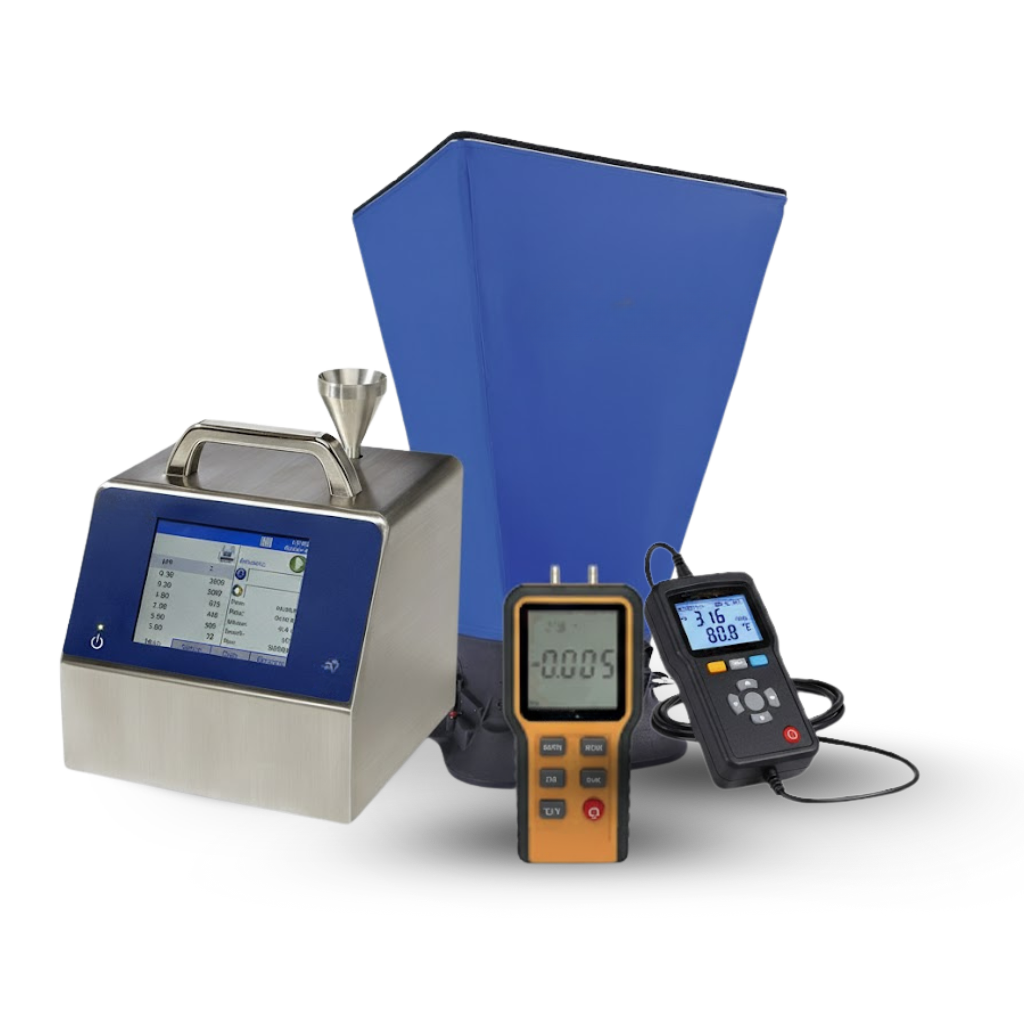

Certified Testing to Prove Your Cleanroom’s Performance

Cleanroom Testing and Validation with Certification

Stay compliant and audit-ready with our full suite of validation services — from particle counting and airflow measurement to HEPA filter integrity and ISO certification. Every report is traceable, transparent, and recognized by international standards.

Precision-validated. Globally compliant. Audit-ready

Our comprehensive testing and validation services ensure your cleanroom meets the highest ISO and GMP standards — delivering proven performance and full regulatory confidence.

- Sound & Noise Level Test

- Smoke Visualization Test

- Light Intensity Level Test

- Airborne Particle Count Test

- Airflow Volume / Velocity Test

- Airborne Microbial Sampling Test

- General Temperature & Relative Humidity Test

- Room Differential Pressure Test

- HEPA / ULPA Filter Integrity Test

- PSL Challenge (Total Leakage Test Method)

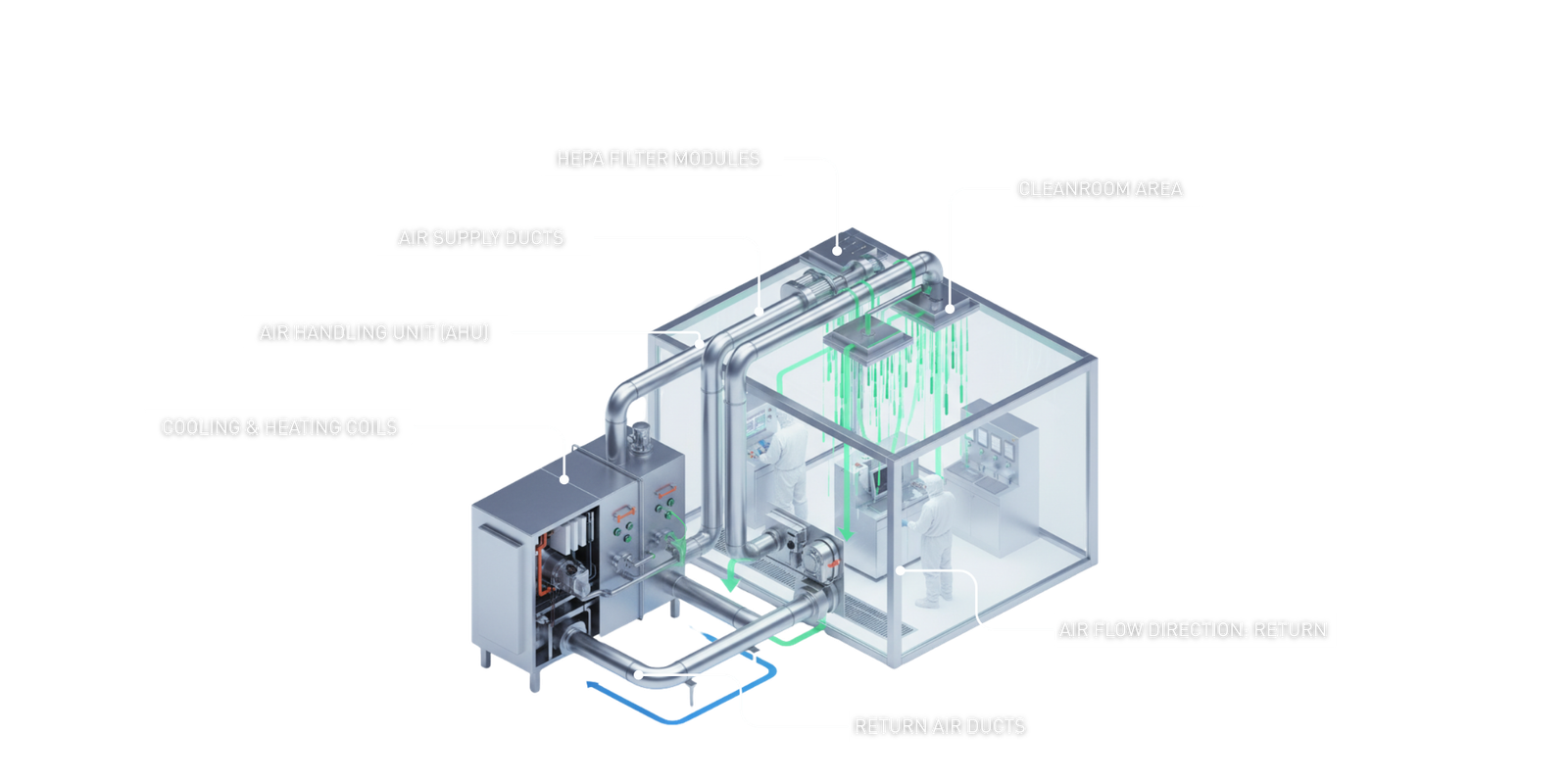

HVAC System

HVAC Systems Engineered for Total Contamination Control

Our HVAC systems are purpose-built for cleanroom environments, delivering precision control over temperature, humidity, and pressure. Designed for efficiency and reliability, our systems help you maintain consistent performance while reducing operational costs.

Flooring Solution

Seamless Protection from the Ground Up

Our ESD flooring systems provide the foundation for contamination control. With antistatic, chemical-resistant, and seamless finishes, we ensure durable, compliant, and easy-to-clean surfaces for pharmaceutical, semiconductor, and food production facilities.

Solutions include:

- ESD Vinyl Flooring

- ESD Epoxy Flooring

- Conductive Tile Systems

Precision You Can Stand On.

Your Reliable Partner for ESD Flooring

Expertise in Cleanroom-Compliant Flooring Systems

Decades of specialized experience ensuring every surface meets strict ISO and ESD standards.

Certified Materials and Precision Installation

Only quality-assured materials installed with exacting precision for lasting performance.

Seamless Integration with Panels and HVAC Systems

Engineered to connect flawlessly with wall, ceiling, and HVAC structures for full-system harmony.

Long-Term Durability and Compliance Assurance

Built to endure heavy use while maintaining compliance, integrity, and appearance year after year.

Cleanroom Equipment

Reliable Equipment for Every Critical Process

From pass boxes and air showers to laminar flow units and FFUs, we provide high-quality cleanroom equipment built for performance, safety, and compliance. Each unit is tested and integrated seamlessly into your facility design.

Cleanroom Classifications

Selecting the right Class for your needs!

| ISO Class | Maximum Particles (ft ≥ 0.1μm) | Typical Applications |

|---|---|---|

| ISO 8 | 3,520,000,000 particles/m³ | Packaging areas, some food production, basic clean manufacturing |

| ISO 7 | 352,000,000 particles/m³ | Pharmaceutical prep areas, general lab clean zones |

| ISO 6 | 35,200,000 particles/m³ | Optical assembly, biotech research, implant production |

| ISO 5 | 100,000 particles/m³ | Sterile drug filling, critical medical device manufacturing |

| ISO 4 | 10,000 particles/m³ | Hard drive manufacturing, advanced optics, aerospace tech |

| Class (FS 209E) | Particles per ft³ ≥ 0.5μm | Equivalent ISO Class |

|---|---|---|

| Class 100 | 100 | ISO 5 |

| Class 1,000 | 1,000 | ISO 6 |

| Class 1,000 | 10,000 | ISO 7 |

| Class 100,000 | 100,000 | ISO 8 |

When choosing the right cleanroom for your application, it’s crucial to assess:

- The level of contamination sensitivity required for your process or product.

- The regulatory requirements for your industry.

- The environmental controls necessary for maintaining cleanliness.

Frequently Asked Questions

Everything You Need to Know About Building and Maintaining a Compliant Cleanroom

What is a cleanroom and how does it work?

A cleanroom is a controlled environment designed to limit airborne particles, dust, and contaminants. It uses HEPA or ULPA filters, controlled airflow, and positive pressure to maintain air purity levels according to ISO 14644 classifications—essential for industries like pharmaceuticals, semiconductors, and biotechnology.

How do you design and build a cleanroom that meets ISO standards?

Cleanroom design starts with understanding process requirements and ISO classification goals. It involves planning airflow direction, zoning, filtration, and materials that minimize contamination. Professional cleanroom contractors use modular panels, ESD flooring, and precision HVAC systems to meet ISO and GMP compliance efficiently.

What is involved in cleanroom testing and validation?

Cleanroom validation verifies that the environment meets its designed performance levels. Key tests include particle count measurement, airflow and pressure testing, filter integrity, temperature, humidity, and microbial sampling. A validation report ensures compliance with ISO and GMP regulations and keeps facilities audit-ready.

How often should a cleanroom be tested or certified?

Cleanrooms should be tested at least once a year or after any major modification. Regular certification maintains ISO compliance, ensures optimal system performance, and prevents contamination risks—especially in high-sensitivity industries like electronics and pharmaceuticals.

What materials are best for cleanroom walls, ceilings, and flooring?

The most effective materials are non-porous, easy-to-clean, and antimicrobial. Common choices include sandwich panels for walls and ceilings, and ESD vinyl or epoxy flooring for static control and seamless protection. These materials support durability, hygiene, and compliance with cleanroom standards.

Your Cleanroom Starts Here.

From design to certification, we handle every phase with precision.

Build your cleanroom with confidence. Our turnkey solutions ensure every detail—from structure to airflow—is engineered for compliance, performance, and lasting integrity.