Cleanroom Construction in the Philippines: Why Manufacturers Need It Now More Than Ever

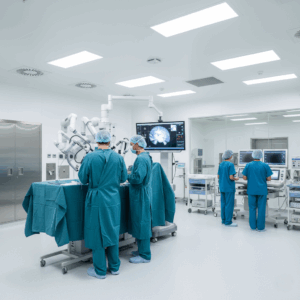

In today’s Philippine manufacturing landscape, precision, quality, and compliance define success. Whether you’re producing electronics, semiconductors, pharmaceuticals, or food and beverage products, one invisible element can make or break your operations: environmental control.

That’s where Nupon comes in. We specialize in cleanroom construction and turnkey cleanroom solutions that help manufacturers achieve global standards—while keeping operations efficient, compliant, and future-ready.

With branches across Laguna, Batangas, Cavite, Clark, Subic, Pampanga, Cebu, and Baguio, Nupon delivers fast, localized support, ensuring your facility meets ISO and GMP standards no matter where you operate in the Philippines.

Why Manufacturing in the Philippines Needs Cleanrooms

As the Philippines cements its role as a regional manufacturing hub, industries face growing demands for ISO-certified cleanroom environments and GMP compliance. A professionally designed cleanroom ensures that your facility meets these requirements while maintaining productivity and profitability.

Cleanroom Solutions for the Manufacturing Sector

| Service | Description | Benefit |

|---|---|---|

| Design & Build | Layout, modular walls, and airflow design that meet ISO 14644 standards. | Efficient and compliant cleanroom setup. |

| HVAC & Filtration | HEPA/ULPA filters and laminar flow systems for clean, stable air. | Protects products and ensures air purity. |

| Validation & Certification | Full testing and compliance checks for ISO and GMP standards. | Audit-ready and regulatory compliant. |

| Equipment & Consumables | Air showers, pass boxes, LED lighting, and other contamination-control tools. | Fully equipped and safe cleanroom environment. |

| Flooring Solutions | Anti-static, seamless, and chemical-resistant flooring built for cleanrooms. | Prevents contamination and supports ESD protection. |

Why Manufacturing Areas Need Cleanroom-Level Control

Even outside pharmaceutical or medical sectors, manufacturers benefit from cleanroom principles:

| Challenge | Cleanroom Solution |

|---|---|

| Dust and airborne particles affect precision | HEPA/ULPA filtration with laminar airflow |

| Static discharge damages electronic components | ESD-safe flooring and grounded panels |

| Temperature and humidity impact quality | Automated HVAC and environmental monitoring |

| Cross-contamination between work zones | Airlocks and modular wall segregation |

| Equipment and product validation | ISO-compliant cleanroom testing and certification |

Cleanroom systems help maintain process repeatability, reduce product defects, and extend equipment lifespan — translating to measurable gains in productivity and compliance.

Certified. Controlled. Compliant.

From concept to certification, Cleanroom Construction delivers turnkey cleanroom environments tailored for the unique demands of manufacturing sectors.

Our engineers ensure every cleanroom meets your operational goals — balancing contamination control, energy efficiency, and sustainability.

Ready to upgrade your manufacturing area?

👉 Explore Our Cleanroom Design & Installation Services

👉 Get a Quote