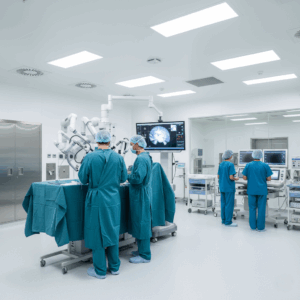

Controlled Environment Solutions for Chemical Processing & Industrial Formulation Facilities

In the chemical processing industry, maintaining controlled environments is not just about hygiene—it’s about operator safety, contamination prevention, airflow direction control, and hazardous fume management. From adhesive mixing rooms to specialty chemical blending zones, reducing airborne particles and controlling airflow can significantly improve quality consistency, safety compliance, and batch traceability.

NuPon provides engineered solutions to help chemical manufacturing plants create safer, cleaner, and more controlled production environments.

Targeted Solutions for Chemical Manufacturing Environments

✅ Recommended Equipment for Industrial Hygiene & Safety

- Fume Hood – Essential for handling volatile solvents, adhesives, and lab-scale chemical formulation tasks.

- Fan Filter Unit (FFU) & HEPA Filtration – Controls airborne particulate contamination in precision blending or packaging lines.

- Cleanroom Pass Box – Enables safe material transfer between controlled and general processing zones.

🛠 Engineering Services for Operational Safety and Clean Control

- Wall & Ceiling Sandwich Panel Enclosure – Segments chemical processing zones to isolate volatile or sensitive operations.

- Cleanroom Testing & Validation Services – Supports audit preparation and ensures airflow and containment systems are operating effectively.

Strategic Application Areas in Chemical Processing Plants

- ⚗ Formulation Labs & R&D Units – Control fumes and particles during small-batch development.

- 🧴 Adhesive, Resin & Polymer Mixing Areas – Reduce cross-contamination and improve batch stability.

- 📦 Filling & Packaging Lines for Chemical Solutions – Maintain clean transfer conditions to prevent product degradation.

- 🔁 Material Transfer Zones – Use pass boxes to reduce contamination when moving chemicals between stages.

Quick Comparison Table

| Solution | Primary Function | Ideal Application Zone |

|---|---|---|

| Fume Hood | Operator protection from fumes | Lab-scale mixing & solvent prep |

| HEPA FFU Air System | Airborne particle reduction | Precision blending & packaging |

| Pass Box System | Controlled material transfer | Mixing-to-packing handoff |

| Panel Enclosure System | Isolated controlled rooms | Hazardous chemical segmentation |

| Validation Service | Performance & compliance check | Safety & airflow audit prep |

Improve Safety, Reduce Contamination, Enhance Batch Consistency

Industrial chemical operations face unique challenges—volatile compounds, temperature-sensitive reagents, cross-contamination risks, and operator safety concerns. Through airflow management, fume extraction, and modular containment, production facilities can operate more safely while improving product consistency and reducing accidents or shutdown interruptions.

Build a Safer and More Controlled Chemical Processing Line

NuPon delivers scalable containment, air filtration, and fume management solutions to support high-performance chemical workflows—from R&D labs to full-scale manufacturing lines.

A Foundation for Safe and Consistent Production

From chemical mixing rooms to precision filling areas, our containment and airflow solutions protect your processes — ensuring operational safety, precision, and reliability in every batch.Upgrading plant safety or building a new isolated process room?

👉 Explore Our Cleanroom Construction Services

👉 Get a Quote